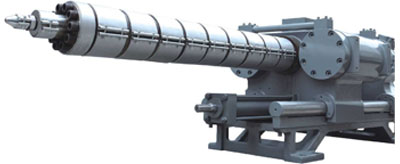

INJECTION UNIT

Short and forceful double-cylinder injection system is used to ensure the steady injection motions. The strain free fixed mold plate and screw assembly with optimized design help to reach better plasticizing capacity and effect. The screw head and back stop ring made of Japanese high tenacity hot working tool steel by special heat treatment features high temperature resistance, ware endurance and hot burnout resistance, maintaining extremely high hardness during high temperature operation. The screw and barrel made of high-grade alloy steel by vacuum ion nitriding treatment feature high hardness ,corrosion resistance and wear endurance.

PID temperature control in combination of high precision electronic ruler and control regulate the speed and pressure of inject ion, pressure keeping smelting, back pressure and other motions to ensure the quality of formed products and continuation of production. Auto material Preparation, drooling proof , and anti cold start lapse function ensure the high efficient, simple and safe operations. High-precision machines used tow-shot move the fuel tank ,as well as the linear guide rail, accurate ,low-resistance.

MOLD CLAMPING UNIT

The new generation mold clamping structure and computer emulation optimized parameter makes motions of the moving plate fast and steady when combining the box type moving plate, fixed plate and high rigidity toggle structure, the characteristic of high strength and anti-fatigue is secured. As compared with similar machines , it owns bigger internal space between tie bars , mold space and mold opening stroke and may process plastic products of bigger size.

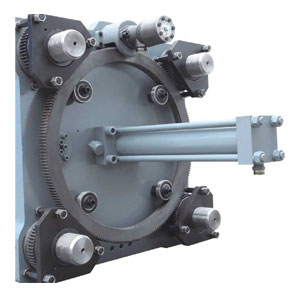

MOLD ADJUSTING UNIT

The automatic mold adjusting devices driven by hydraulic motor adopts gear coupling drive, features steadiness, speediness, high-efficiency and saving mold loading time.

SERVO CONTROLLER PART

The Characteristics of servo saving Injection Molding Machine

High precise Control

The servo System can control the machines’ pressure, speed and location precisely makes sure that the error of accurate repeatability Precision for the shot measure is <0.3%. So thet it can achieve the precision Injection Molding Machine.

High Sensitive response

Because the motor vector is matched with the controller accurately, it just takes the 0.05S when input the number from 0 to max. Compared with other traditional hydraulic injection molding machine, S series machine’s speed is obviously more quickly, each cycle time is shorter, the production efficiency is higher.

Low noise

Compared with the traditional fixed pump and variable pump system the noise will be lower 1/10 under normal circumstances. What’s more , the noise of overall system will be less then 80dB when under the high-speed circumstances. So this series is more suitable for the sealed dustless workshop.

Energy-Saving

Overall efficiency is more 10% and the driving capacity is more 18% than the common machine. Related to the energy saving, this series Can save energy about 30%~80%, with the first-class energy efficiency.

The cooling water saving

The system condition prevent high pressure unloading without any power output leads to the cooling water saving.

THE VARIABLE PUMP ENERGY SYSTEM

High efficiency, energy-saving and high precise proportional pressure and flow variable displacement pump system make the out of the hydraulic system matching the required power for entire machine operation without loss of high pressure throttle and overflow energy. As compared with constant displacement pump ,it saves power by 30%~60% . A motor with same power may be fitted with oil pump of bigger displacement and thus accelerates the speed of machine. Besides, the low oil temperature will prolong the services life of sealing elements. Use of imported high performance precise oil filter device will further prolong the normal service life of hydraulic oil and also ensure the normal operation of hydraulic system. Buffer device is used in every mold opening and clamping oil way to ensure steady mold opening and clamping operation without any impact. Besides, differential mold clamping operation is fitted to ensure high production efficiency.

INJECTION MOLDING CONTROLLER

It is controlled by Double CPU. The system HML uses X86 300MHz technical grade Display. The system employs A RISC 140MHz microprocessor, with high speed, noise-immunity, fan-less, ang OW power Consumption. Independent control improves the performance of stable.

The display is 8.4” screen and resolution is 800*800, User-friendly screen and many options of language.

One USB (2.0) port and two Ethernet (100-BaseT) port are provided.

7 + 1sections PID temperature control, the temperature is 1 C

32points input, 32 points output. It can extended and have the function to replace trouble spots.

The Linder Transducer’s resolution is 1/65535, so High-resolution makes the control more accurate.

120 technological parameters access can be stored or uploaded with an ordinary USB drives

Injection end and the temperature tracking is Curve Display, dynamic recorder Parameter is modified, Dynamic Warning is exhibited, all these make the operation more convenient.